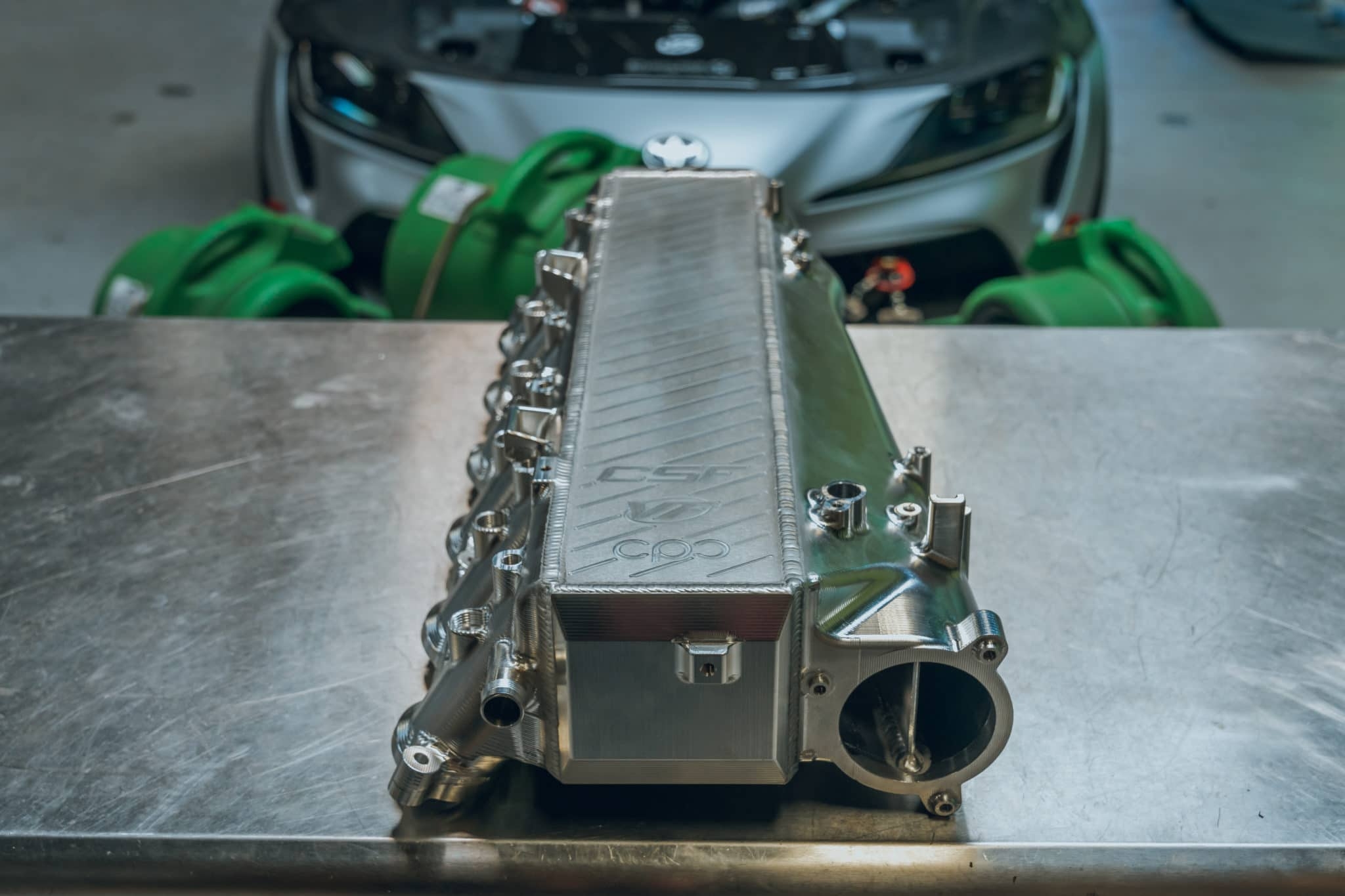

CF Racing “Super Manifold” GR Toyota Supra A90/91 Supra And BMW B58

£3,720.00 ex. VAT £4,464.00 inc. VAT

Description

- Utilizes a High Performance, Motorsports-Grade Bar/Plate Air-to-Water Intercooler Core

- Double the Capacity of the OEM Core (12 Rows of Water Cooling vs. OEM 6 Rows)

- Significantly Lower Pressure Drop Across the Core Compared to OEM

- Designed in SolidWorks Using Computational Fluid Dynamics (CFD)

- Integrated Air Divider in Inlet Tank Evenly Distributes Airflow Throughout the Core

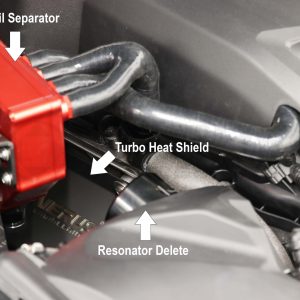

- Easy Access to Spin-Off Oil Filter for Quick Oil Changes – No Need to Uninstall Manifold Every Oil Change

- Counter Balanced Design for Optimized Airflow

- Integrated Sensor Pad with Three 1/8″ NPT Ports to Measure Additional Parameters

- Included Optional Fuel Rail for Top Feed Port Injection

- Individual Port Injection Bungs on Each Cylinder Runner (Comes Pre-Plugged)

- Individual 1/8″ NPT Ports on the Top of Each Cylinder Runner for Nitrous or Meth Injection

- Allows for Even Spray Distribution and Control for Maximum Performance and Engine Protection

- Individual 1/8″ NPT Breather Ports for Both Inlet/Outlet Water Connections on Back of Manifold for Easy Air-Bleeding of the System

- Plug-and-Play design, Requiring No Modifications to Install

- Includes Hardware and Installation Kit with Picture Diagrams Containing 28 Different Parts for Easy Installation

- Can be Used With OEM or Aftermarket Engine Covers (with OEM Connections)

- Comes Finished in Raw Billet Aluminum – Made by World-Leading Automotive Machinist Custom Plenum Creations in Australia

With well over 1,500 hours of design, prototype development, machining, and testing, CSF, along with partners VF Engineering (USA) and Custom Plenum Creations (Australia), has now brought a state-of-the-art CNC machined, high-performance Charge-Air Cooler Manifold to the B58 platform for Mk5 Supra and BMW models. This product solves what has been commonly known as a weak link of an otherwise impressive new engine platform.

With the larger and more efficient water-to-air intercooler performance, lower pressure drop across the system, included fuel rail, kit for top feed port injection, and several other industry-leading features, the CSF Super Manifold will allow B58 owners to maximize the performance of their vehicles and push the limits further than what has been previously possible with this new platform.

CSF’s Creates the Missing Link to Maximum B58 Performance

The newer 2nd gen B58 engine, found in the Mk5 Supra, has already been proven to be an incredible platform for performance enthusiasts – taking the performance and motorsports industry by storm in just a couple of years since its release. In a short amount of time, performance enthusiasts have already started to more than double the stock engine output – now pushing through 700whp, 800whp, and looking into the elusive 4 digit 1,000whp mark.

The OEM water-cooled charge air cooler intake manifold for the B58 engine is adequate in cars with little or no modifications, but starts to really show an apparent weakness in cars that have bolt-on modifications, turbo upgrades, increased fueling (such as port injection), and performance tuning. Also, the OEM intercooler system has been known to suffer from heat soak in demanding racing conditions such as time attack, endurance racing, drag racing, and drifting, as well as spirited driving on the street. This can cause the car to pull timing out of the engine due to high intake air temperatures (IATs), and then can cause “limp mode” once temperatures reach a certain threshold, as the vehicle’s ECU will cut power to protect the engine.

CSF conducted extensive testing on the dyno with R&D partner VF Engineering to ensure performance improvements before going into production with the new manifold. We performed over 50 dyno runs on the same car, on the same day, in relatively hot ambient conditions (~90°F) comparing the performance of the CSF Charge-Air Cooler Manifold to the OEM. Both the CSF and OEM cooler went through roughly 25 back-to-back dyno pulls every 30 seconds to measure the performance of the car overtime, resistance to heat soak, recovery time, and the effect on the turbo system duty cycle.

Reputable automotive website and performance part testing specialist, MotoIQ, was on site to witness and assist in organizing the testing to validate the accuracy of the claims made by CSF on the improvements and benefits of the upgraded manifold. The results were published independently by MotoIQ and are now available on their website – read the article here for more specific details on the increased performance of the CSF B58 upgraded intake manifold.

Summary of Testing

- Faster recovery of intake air temperatures

- ~30°F reduction of intake air temperatures (IAT’s) compared to OEM

- Less pressure drop compared to OEM core

- Puts less stress on the turbo system, allowing more boost to be made at higher targets

- Avoided going into limp mode after prolonged demanding conditions, simulating motorsports use

- On a stage 2 car with bolt-on upgrades, making ~400whp, comparing dyno run 19 between CSF and OEM, an increase of ~26whp and 11wtq were achieved

- The performance increase and delta between CSF and OEM will be bigger as power is increased in the vehicle

Civic

Civic  Integra

Integra  NSX

NSX  S2000

S2000  IS

IS  IS-F

IS-F

MX5

MX5  RX7

RX7  RX8

RX8  EVO

EVO  EVO X

EVO X  GTO

GTO  200SX

200SX  300ZX

300ZX  350Z

350Z  370Z

370Z  GTR

GTR  Pulsar

Pulsar  Skyline

Skyline  BRZ

BRZ  Forester

Forester  Impreza

Impreza

Aristo

Aristo  Celica

Celica  Chaser

Chaser  GR Corolla

GR Corolla  GR Yaris

GR Yaris  GR-86

GR-86  GT-86

GT-86  MR2

MR2  Soarer

Soarer  Starlet

Starlet  Supra A90

Supra A90  Supra MK4

Supra MK4